- 3104 South Elm Place, Suite I, Broken Arrow, Oklahoma 74012

- info@drbcoolingtowers.com

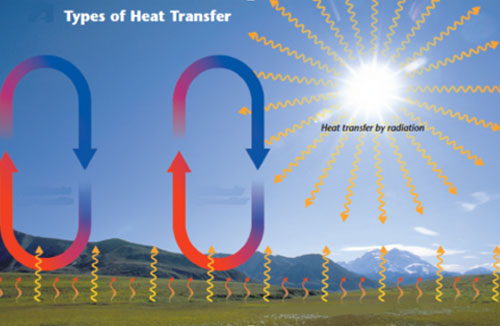

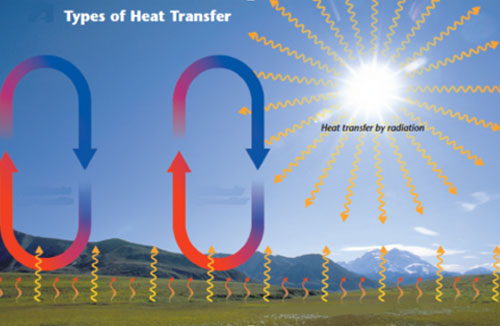

Heat Transfer

Heat Transfer

Fill Media – it all starts here. Whether you have a Counterflow or Crossflow tower, one of the most important maintenance items is your Fill Media. This is where the whole “air- water transfer” takes place, or as it is sometimes called, where the “business end” of operations occurs. You can take it to the bank that without good saturation and water-air flow transfer through the fill and down to your coldwater basin, you are never going to get the proper waste heat extraction to the atmosphere that you want and that good cooler water pumped back into your system to consume more of the heat in your process. Bad Fill Problems can rob your Cooling Tower of 30-40% of its performance. Here are things to look out for in your Fill to insure good operation:

a. Collapsed or Sagging Fill. This always causes water to run to a low point and “corridor” or pool there. This causes more air to go through the resulting dry areas, which are supposed to be wet, and your tower performance drops exponentially.

b. Proper Alignment of Fill. If you have large gaps you are probably aren’t getting enough breakup of your water. If there is not a smooth interlocking fit and the media appears too close together you are probably restraining air flow.

c. UV Damage. UV sunlight can prematurely destroy your fill media. PVC material absorbs damaging rays and becomes brittle over time, leading to disintegration.

Drift Eliminator – Drift Eliminators in Cooling Towers are designed to keep water from going up to your fans and also keep good air flow circulating. When your Drift Eliminator is in poor condition it just increases all your costs with all the water usage because of carryover. This water drift can damage everything, including the mechanical equipment inside and structural components outside the tower. That is why it is so extremely important to replace deteriorated Drift Eliminators. If you have plugged cells in the drift fill that also needs to be kept clean so there is no air flow restriction.

Louver Areas – You need to make sure you also examine the exterior of your Cooling Tower to make sure it is operating correctly with no carryover or splashing of water. Drain boards need to be inspected also. Heat transfer areas like the Fill, Drift Eliminators, and Louvers are essential to waste heat extraction and need to be maintained at a Combined Cycle Power Plant to ensure effective operation.