The DRB Industries Blog

July 16, 2017

A leading supplier of cooling tower parts and components has announced the publication of a website blog designed to assist cooling tower operators.

The blog, located at drbcoolingtowers.com will feature commentary on the cooling tower industry and provide maintenance tips and instruction.

July 16, 2017

Check to make sure you have enough oil in your Gear Boxes. You also need to do some oil analysis from time to time to check for wear and foreign particulates. Check your seals to see if they are leaking. Examine backlash and endplay to make sure all shafts, gears, and hardware are working correctly.

July 16, 2017

Structural components are also areas of great concern. Older Cooling Towers often have aging wood components, whether it be structural, stairways, walk ways, etc. Deteriorating framework and wood members can cause serious problems if left unaddressed. Loose or missing bolts and fasteners are an indication of an accident just waiting to happen

July 16, 2017

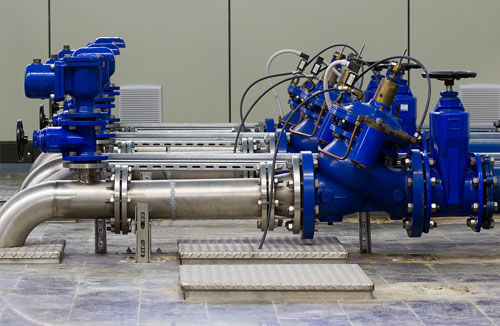

It is vitally important to check nozzles that might be plugged along with your pipes. These should be inspected and cleaned on a regular basis if needed. It is important to have good water distribution over the entire tower. Nozzles, whether in up-spray or down-spray mode, should be checked to see if they are spaced and operating effectively.

July 16, 2017

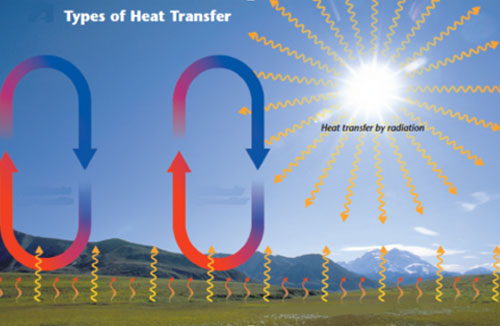

Fill Media – it all starts here. Whether you have a Counterflow or Crossflow tower, one of the most important maintenance items is your Fill Media. This is where the whole “air- water transfer” takes place, or as it is sometimes called, where the “business end” of operations occurs.

July 16, 2017

David Brumbaugh – President of DRB Industries One of the most important maintenance concerns at a Combined Cycle Power Plant and often the most neglected is the Cooling Tower. Operators ask all the time, “Why am I not getting the thermal efficiency that other plants do and what can I do to increase my performance?”