Cooling Tower Fans and Related Parts

Inspection Tips

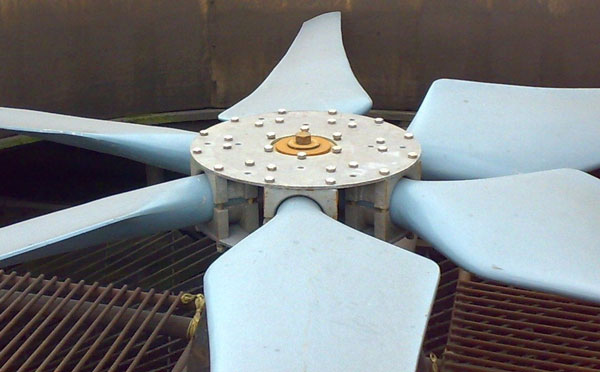

Check to be sure that the bushing and its hardware are in good condition and that the fan bushing is tight on the motor shaft. Check the joints between the support and its motor mount. Look for erosion or corrosion on the blades, especially near welds and between the end plates and blades.

Adjustable-pitch propeller fans have bolted connections between the blades and the hub and some means of readjusting the blade pitch angle. Check these blades for signs of erosion, corrosion, or excessive buildup of deposits. Carefully measure the pitch angle of each blade. Readjust the blades within 1-2° of manufacturer’s recommended pitch angle. Check the condition and tightness of the hardware attaching the hub to the blades. If there is a hub cover, examine the connections between it and the fan hub.

Check the overall condition of the fan cylinder material, especially all welds in steel shrouds. Check the tightness and condition of all the assembly and hold-down hardware. Examine adjoining segments for any leaks. Using the longest fan blade, measure the fan blade tip clearance around the cylinder. You can adjust tip clearance by adjusting the support or cylinder according to manufacturer’s instructions.