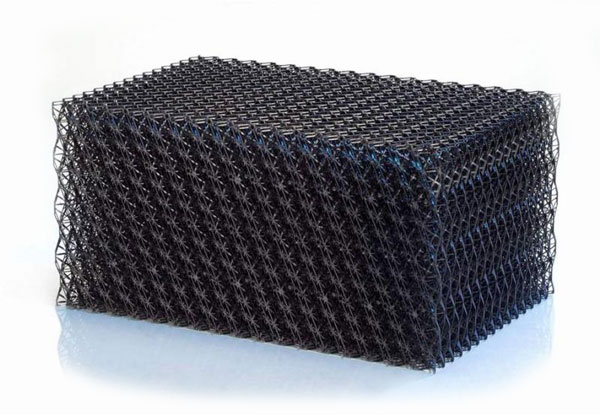

Cooling Tower Fill Media

Cross Fluted media splits the water stream as it descends throughout the fill pack. Herringbone media distributes water evenly over the entire fill area for high thermal performance. Offset Vertical media combines the low-fouling characteristics of vertical flow with the enhanced water distribution of the Cross Fluted design. Vertical Flow media has large openings and high velocities to create an anti-fouling environment. All our film fill is available in various options for you in site assembly, glue assembly, or mechanical assembly.

Fill Media Inspection Tips

Make sure the Fill Media is not sagging horizontally, which causes water to run to the lowest point instead of distributing evenly. This sagging allows for easier air passage in areas with less water. Fill Media which is spaced too far apart also doesn’t break up water efficiently. Fill Media in poor condition reduces your performance by 30 or 40%.