Drive Shafts and Couplings

Drive Shafts

They are light weight and corrosion resistant unlike steel Drive Shafts. This allows for long spans which eliminate the requirement for high maintenance. The Composite Drive Shafts also have a very low coefficient of thermal expansion. Our Drive Shafts use 316 stainless steel for flange hubs, bushings, and hardware. Fewer parts at each flex disc connection makes for easier installation. Each Drive Shaft is tested prior to shipment to 4 times continuous operating torque and are dynamically balanced to AGMA 9000-C90, Class 9 specifications.

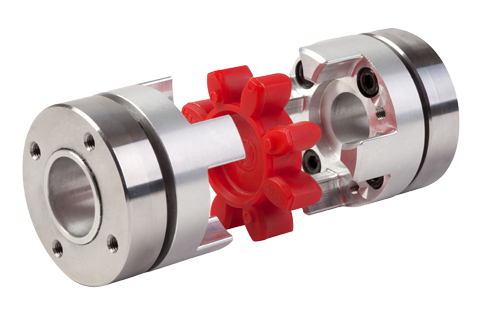

Couplings

Inspection Tips

Use an approved method, like an optical device or dial indicator, to check the alignment of your Drive Shafts and Couplings. Look for signs of corrosion or other damage on the tube, especially near welding.

Check the connections between the flex elements and the tube. Check the connections between the coupling halves and the motor and gear box shafts. Carefully inspect the metallic flex elements for evidence of corrosion or fatigue. Inspect the elastomeric flex elements for cracks, brittleness, or other signs of wear.

If your Drive Shaft has more than one span, check the mid-span bearing carefully and lubricate as necessary. Be sure to check the alignment of both shafts and ensure that the bearing hold-down hardware is in good working condition and tight. If replacement of a component of a two-shaft system is necessary, look into replacing the entire system with a single span shaft. This will dramatically reduce maintenance costs.